Custom

Moldings

|

|

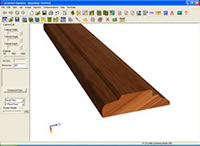

Within eCabinet Systems, you can design pretty much any profile using the CAD-like Contour Manager. From this you create a “tool” that can be used in the software to put this custom profile on a part. The part can be a molding or an edge profile of a door, table top or pretty much anything. The profile can be put on a straight edge or a curved or serpentine edge. This part can then be used in an eCabinet Systems cabinet or assembly.

|

When it is time to actually make the part, the profile information is sent to the machine control as part of the CNC file transmitted from eCabinet Systems to the Thermwood CNC control. At this point, you have an alternative to the traditional approach to cutting the profile.

Traditionally, you would either grind a tool to the correct profile or you would have a tool made with the correct profile. This works well if you must make a reasonable number of parts. If you only need a few parts, or perhaps you only need one, our new approach may be more practical.

|

With this new approach, if you do not have a proper tool, the machine control automatically develops a modeling program to cut the profile using standard modeling tools. Modeling tools are typically a ball nose cutter, a flat bottom cutter and a liner or pointed tool.

These tools run back and forth along the length of the part, developing the profile by shifting over a small amount each pass. The final shape is relatively smooth and, with some light scuff sanding, is ready for finishing.

This does require a bit longer to cut then when using a traditional tool. A typical eight foot length of molding however, can be modeled in about 10-15 minutes. This approach also offers the ability to model wide and complex moldings that would otherwise require very expensive tooling and highly specialized machinery. You can machine a 12 or 14 inch molding as easily as a 2 inch molding, it just takes a little longer. Just imagine a 12 inch wide, curved molding over a door. The possibilities are endless.

This custom molding capability brings real flexibility and new opportunity to the custom shop and it is a standard part of eCabinet Systems and a standard feature of Thermwood’s CNC control.