Straight Talk about Nested Based SystemsCost Performance Comparison Nested based systems, which include cabinet design software, a CNC router and high flow vacuum table are offered at prices that range from about $25K to over $150K. As with virtually any type of equipment, lower cost systems offer limited capability and lower performance; higher cost systems offer greater capability and better performance. Each cabinet shop considering this investment must determine the proper balance between capability, performance and price. There is no one right answer for everyone. Selecting the best balance between price and performance is an individual decision. Today, however, gathering the fundamental information to make this determination is difficult at best. This is especially true because each equipment vendor focuses on only those features that benefit them and some information promoted to the industry is simply not accurate. This document is intended to present, from the user’s standpoint, a comparison of the capabilities and limitations of nested based systems. Since it is being developed by Thermwood, information concerning Thermwood’s offering is accurate. Other systems have been grouped by price point. Specific vendor offerings at each price point may vary from that shown but the overall view of each area is accurate. If you are considering a system other than Thermwood, you should independently determine capability and price to assure complete comparison accuracy. Note that in addition to eCabinet Systems, other commercially available software can be used with a Thermwood CNC router although these combinations are not shown.

Straight Talk about Machine Cost and Performance With CNC routers, in general you get what you pay for. Higher price machines offer more capability and better performance; low cost machines offer less capability and lower performance. You must determine the level of capability and performance you actually need. To make this decision you need a basic understanding of what is available at each price point. This is difficult because misleading, deceptive and confusing technical specifications are common. Some machine specifications published and openly promoted in the woodworking industry cannot be actually achieved in real life by Defense Department systems costing over $50 million. They are simply lies. You cannot use published specifications to compare CNC routers today. The honest folks will lose. Low cost systems tend to be modest structures, some which you assemble yourself. They generally use a PC as the control, which may or may not be part of the base system price. They tend to operate at somewhat slower, but generally acceptable speeds. Accuracy for these systems is defined by mechanics. Accuracy of linear ways and drive mechanics determine how accurate the machine is. Because of cost constraints, these are not high precision components. A mechanically accurate ground lead screw typically cost more than the total price of these machines. This means that you cannot expect super accuracy from these systems, but in most circumstances the accuracies they offer adequately does the job. These systems, as long as they are properly aligned and square, are substantially more accurate than measuring and cutting parts by hand. And, they are quite a bit faster. You may encounter problems if you try to process complex joinery, but for basic butt and dado joints these systems are adequate. Mid-range systems tend to be a little more mechanically robust. They generally run high enough speeds that actual cutting speed is dictated by the cutting tool and material and not by the machine. These systems commonly use low cost CNC controls and lower cost drives, which execute programs generated elsewhere. These controls offer little machine specific capability but perform basic CNC functions well and are fairly reliable. The only possible shortcoming for nested based machining is that they may not store more than a couple programs at a time. Most software outputs jobs to the machine as a multitude of programs, so this limitation may cause delays and confusion. Some companies use a separate PC to store and feed individual programs to the control to address this issue. Like low cost systems, accuracy of mid-range systems is defined by machine mechanics. Mechanics can be more robust and may hold alignment better over time, but precision components are still not possible. Again, the resulting accuracy is adequate for most nested based machining with the possible exception of precision joinery. High-end systems, including Thermwood, tend to be better engineered using higher performance, higher cost drives and components. This results in higher machine performance and better accuracy. Most companies in this market use sophisticated CAD design, stress relieved engineered structures and laser alignment. The major difference between machines in this market is the CNC control. Thermwood develops and manufacturers its own high-end CNC control and the other manufacturers generally use commercial CNC controls developed for the metalworking industry. In either case, these controls offer more features, larger program storage and generally better performance and represent a significant point of difference from the much more limited controls of the mid-level systems. Speeds are well above the maximum practical cutting speed and tend to be about the same for various models in this market. Super high-speed systems have been a commercial failure, so most companies have settled down to offering good practical performance. There is one caveat, however. Some have opted for heavy, high-mass moving axes which can result in performance issues in certain circumstances. Some commercial metalworking CNC controls use traditional servo loops to move each axis. When this arrangement is used to quickly move a massive axis around a sharp corner, unacceptable overshoot occurs. This also occurs when cutting small diameter circles, which is common. The only solution is to dramatically slow machine feed speed or even pause in problem areas. This slows program execution. More sophisticated CNC controls use a system to look ahead in the program which eliminates the problem. These systems keep following error very small and generally don’t have problems with quick motions. When these controls are coupled with modern rigid low-mass engineered structures, you have the best of both worlds. Accuracy for high end systems is achieved using laser compensation. The most serious positioning errors on CNC routers are caused by pitch error in the lead screw or rack that drives each axis. These errors are ignored on low and mid-level systems, however on high-end systems, linear laser compensation measures these errors and creates a compensation table to eliminate them. This does not address other mechanical inaccuracy or misalignment. The only way to address this has been to align the machine perfectly, which is not practical at the current industry price points. A new approach uses three-dimensional lasers to compensate the position of the cutting tool at every point in the working envelope. Currently, Thermwood is the only company in the industry who does this as Thermwood’s CNC control is only one of a couple in the world with 3D compensation capability. It is expected that eventually this will become standard practice. High end systems available today are all fast and accurate enough to perform the functions, joinery and carving needed for every aspect of nested based production. The major differences between machines are centered around control features and how the control interfaces with the design software. This is reflected in many of the differences you see in the comparison chart. Regardless of which system you select, make sure you personally see your system design and run your product. This is the only way to be sure it functions acceptably. This will also help you discover any problems, shortcomings, complications or difficulties that the machine supplier might forget to mention. If they can’t easily design and run product for you, you probably can’t run it either. Lease payments shown are the monthly lease payment for a 60

month lease at 7% with the first payment down. It was assumed that all systems

would qualify for these rates, however, it may not be possible to secure these

rates for lower cost systems or software packages so lease payment levels are

for comparison purposes only. Note that in the

Straight Talk about Cabinet Design Software This is an area with strong opinions, misunderstanding and misinformation. Most design software is sold by companies as a primary business and with these you generally get what you pay for. One high-end package, eCabinet Systems, is not sold but is given to professional cabinet shops by Thermwood for free. This software is not intended to generate revenue directly but is primarily used to sell Thermwood’s CNC routers as well as ancillary software and services. Output of eCabinet Systems is restricted to Thermwood CNC routers and panel saws. The lowest cost software tends to be library based. You work from pre-designed libraries. Only supported modifications to cabinet design are possible. The software is easy to learn and generally provides the core capability smaller shops require, but lacks the higher level of flexibility needed for some custom work. More expensive software is generally parameter based. You start by specifying a large body of parameters that define every aspect of how a cabinet is made. These parameters are used to create cabinets of a specific size and configuration. Some of these packages also include pre-defined libraries. This works well for shops whose basic product design is relatively constant. It does not easily support shops that offer products whose fundamental design and construction varies significantly from job to job. This approach offers much more flexibility than the library approach but requires formal training and more technical effort to fully use the advanced features. eCabinet Systems is also parameter based but approaches the process differently. Instead of defining parameters in text form before creating a cabinet, a seed cabinet with pre-defined parameters is displayed graphically. This three-dimensional cabinet can be moved, rotated, zoomed and exploded. As individual parameters are modified, changes are reflected in the displayed image which can be examined in detail. The resulting cabinet is saved in a library where it can be used and resized or modified further. eCabinet Systems allows multiple cabinets, parts of cabinets and independent components and carvings to be grouped together and saved as “assemblies”. This supports design of complex items and furniture better than a pure parameter based system. As with any parameter based system, there is a learning curve and although the package itself is free formal training is generally required. Each package provides a variety of other capabilities and features with each supplier attempting to promote specific advantages that might entice customers to choose their product. In addition to the purchase price, commercial software packages require payment of additional support and upgrade fees on a continuing basis.

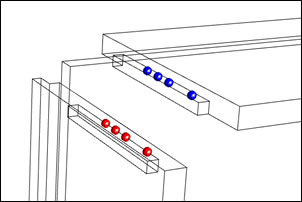

Assembly marks are dimple patterns that are machined into blind dado or full dado joints of mating parts to indicate how parts fit together. This dramatically reduces assembly time, especially for more complex designs. Assembly marks were invented by Thermwood who has applied for patents on them. Other software packages have been granted rights under any patents issued but only for use on Thermwood machines. To date, none have added this feature.

Pretty much any CNC router can machine a carving using a carving program. Lower cost machines tend to cut these at slower speeds. More expensive machines tend to operate faster, however, this is one area where price may not be a good indicator of performance. The basic parameter that determines carving speed is acceleration and acceleration is determined by a whole series of trade-offs the manufacturer must make. If carving will be an extensive part of your product line spend some time verifying carving performance. Don’t just assume every system will do this well. If carving are rarely needed, pretty much any system will work provided you have some way of obtaining or generating the carving program. Software and scanning programs are available to create custom carving programs but this area gets pretty involved and is beyond the scope of this document. Libraries of carving programs are available from Thermwood but they only function on Thermwood machines. Carving programs can be incorporated in eCabinet Systems designs. We believe carving programs can also be used in some higher-end software although they don’t promote this capability so you will need to verify this independently. With Thermwood and eCabinet Systems carving programs can be scaled and positioned on cabinet parts and are displayed in the software. When these parts are output to a Thermwood CNC router, the machine cuts the carving into the component as part of cutting the nest. Carvings can also be cut on solid wood blanks as independent programs. The Thermwood CNC control can scale carving programs in each axis independently without re-programming.

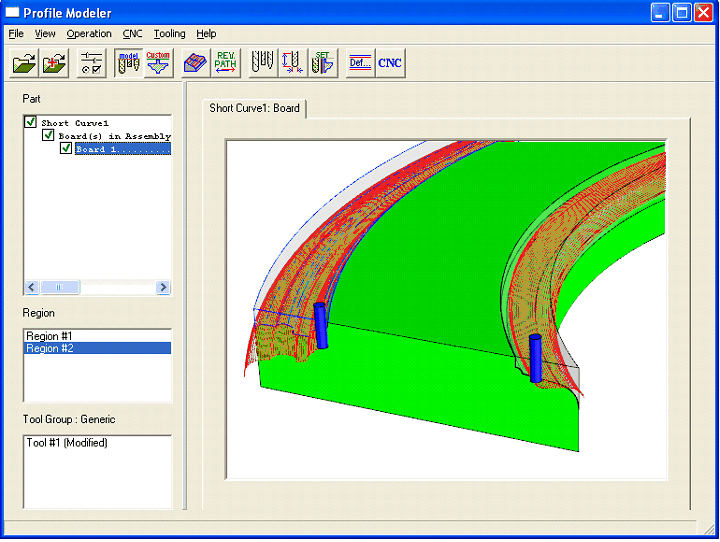

Virtually any profile can be incorporated on a cabinet part or other component in eCabinet Systems. When parts with a custom profile are sent to the CNC router, the machine control requests a matching profile tool. If the tool is not available, the control develops a modeling program using a standard ball nose and flat bottom bit to develop the profile shape using prototype modeling techniques. This technique can be used to create unique profiles, reproduce moldings or finish a job when a profile tool breaks. This feature can also be used to machine wide custom moldings as well as curved moldings. This capability is not currently available on any CNC control except Thermwood’s Gen2 SuperControl.

About Cutting Replacement Parts Cutting a replacement part or parts that were originally in a nest requires a new nest program that includes the required replacement parts. In all systems except Thermwood, this requires that you return to the design software to create the new nest and program. Since Thermwood’s control creates nest programs at the machine, you can simply instruct the control to run the job again, removing everything except the parts you need. You can run the parts as a new nest or add them to a new job that uses the same material. Yield in nested based production, that is, how much material is used and how much is thrown away, is determined by the quality of the nest and whether material left from one job can be used on another job. As for the nest, there is virtually no difference in nesting efficiency between software packages from the least expensive to the most expensive because everyone licenses their nesting routines from the same people. When it comes to reusing partially cut sheets, there is a difference. Every software except eCabinet Systems does nesting and program creation in the office using design software. To reuse material requires that the software know its shape. Some software stores these shapes so they can be programmed into new jobs. Others require you to define the size and shape. Although this sounds simple enough it doesn’t really work very well. Problems stem from having to label, store, retrieve and identify this material. Most shops don’t have systems to do this because there is no need to identify individual sheets of material in normal production. To run a new job using left-over material you have to determine what individual pieces of material are needed, then determine the order in which they will be used and then find the exact pieces called for by the program. If a specific piece can’t be located, you either need to return to the office, re-nest and reprogram or use a full sheet and create even more scrap. Most shops find the extra effort and cost required to store, track and identify this material is not worth the improved yield. They just throw it away. Since Thermwood nests at the machine, this process is much easier. The control prints a bar code label for any remaining panels large enough to reuse. When a new job starts, the control asks if there is any material from old jobs that can be used. The bar code label of any on hand material is scanned. The control nests on this material first, then on full sheets and then prints labels for any remaining panels. In this approach there is no reason to track, store or identify material. Just scan what is available and use it. You can also use material of any shape that doesn’t have a label by defining its size and shape on the machine control although frankly, not too many people do this. The labeled pieces are easy to use and most Thermwood shops use them as part of normal operations. Just the little extra effort needed to define the size and shape of odd panels prevents most shops from using them. The Thermwood control also provides the ability to define areas on the sheet, perhaps with defects, that the system won’t nest in. Again, although this sounds like a great feature, few shops use it. It seems to be much easier to just run the job, discard any bad parts and re-run them. Running replacement parts on a Thermwood is done right at the machine without reprogramming, so it is quite simple. Straight Talk about CNC Programs Just like fingerprints, every CNC router is different. This means you must tailor each CNC program to a specific machine. For example, if two machines have different table sizes and use different sheet sizes, the nest and programs to run a job on these machines will obviously be different. There are, however, many subtle differences between machines that also require machine specific programming. The fact is no two machines are the same. This means CNC programs can’t be easily exchanged between machines. In nested based systems, Thermwood addresses this by not sending CNC programs to the machine but instead sending the job file which tells the machine what you want to make. The machine control builds the nests and creates the CNC programs. Since each machine knows its own configuration, the programs are automatically tailored to that machine. The same job file, however, can be sent to any Thermwood machine and you get the same parts. This makes it practical for Thermwood machine users to run jobs for others and has resulted in an extensive “Production Sharing” network. Thermwood has worked with other leading software suppliers and they are also able to send job files directly to Thermwood machines. Thermwood was the first CNC router manufacturer to offer a rotary playback axis for CNC routers to support carving of three dimensional legs and posts. Since then, several other manufacturers have introduced similar products. Software and scanning systems are available to create custom post and leg carving programs although these systems tend to be somewhat costly today. Thermwood offers a library of carved leg and post programs for a nominal fee but they only work on Thermwood systems. A great deal of interest surrounds these systems but they are not widely used in the cabinet industry. Thermwood is currently the only company in the world that offers high volume wood carving systems in eight and ten spindle models. These are expensive machines that have enjoyed some level of success. Thermwood invests in advanced carving technology primarily targeting these machines but makes sure technical advances can be applied to single spindle cabinet systems. This has resulted in some unique capabilities. For example, each design can be resized at the control in both length and diameter without reprogramming. Shortly, Thermwood will offer the ability to define a turning in eCabinet Systems and then machine the turning on a rotary playback. Programs to simplify the programming of carvings are currently being developed but no release date can be projected.

Straight Talk about Software Compatibility Today there are many software packages used to design cabinets but generally each stands alone and outputs its own nested CNC programs. Today there is no stand alone software that can take output from multiple sources and blend them together into a common nest, however, this can be done by the Thermwood CNC control. It is possible to load programs from a variety of sources such as Cabinetvision, Cabinetware, KCDw, eCabinet Systems as well as DXF files from AutoCAD or any other design software and then nest them all together in a single job. The standard approach to tooling selection is to instruct the CNC program access a tooling position. The machine operator must make sure the correct tool is in each position. The Thermwood control offers a more sophisticated approach with easy to understand graphic display and control of available tooling. You can also assign specific tool groups to different materials. Then, a CNC program will automatically be assigned different tooling based on the material being cut. Job files from eCabinet Systems informs the control what material was specified for the job. The system also keeps track of cutting time on each tool, alerting the operator when tool life has expired. It can also be instructed to automatically substitute a new, sharp tool when a tool’s life expires. About Tool Length Compensation Advanced nested based joints, especially blind dado, dovetail and puzzle joints rely heavily on exact tool length. Even a few thousandths error in tool length results in joints that don’t mate easily. It is not possible to manually insert tools accurately enough for this application. There are some manual adjustment systems offered on some machines but they require skill and time, and errors are common. The most effective approach uses a precision measuring device to accurately measure tool length and then adjust all programs accordingly. If you plan to use this type of joinery, this is pretty much mandatory. Straight Talk about Web Based Technical Support Thermwood offers a Virtual Service program where technicians in the factory access and adjust every aspect of the CNC control, programming and configuration. Virtually anything a service technician can do in your shop can be done remotely using this technology. To accomplish this required significant modifications to virtually every aspect of the CNC control design. No other commercial control manufacturer offers this, so this feature is not available from anyone else today. Since many commercial controls are PC based, some machine manufacturers have set up net meeting software and claimed web service, but this approach is little more than a fancy phone call. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||